PRODUCTION PROCESS OF STRAIGHT SEAM WELDED STEEL P

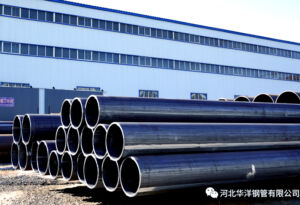

The straight seam electric welded steel pipe is a steel pipe whose weld seam is longitudinally parallel to the steel pipe. During the production process, it carries out cold rolling or hot rolling steel plate or strip coil welding, and then carries out straight seam welding on the welding equipment to form a straight seam welded pipe. The welding process of straight seam steel pipe is as follows: 1、Plate detection: ultrasonic inspection shall be carried out first after entering the production line to manufacture steel plates for large-diameter submerged arc welded straight seam steel pipes. 2、Milling: use the edge…