| Name | Flange | |

| Size | 1/2″ to 80”, DN15-DN2000 | |

| Type | plate, welding neck, slip-on, threaded, lap-joint, socket welding and blind | |

| Pressure: | ANSI: 150#300# 400# 600# 900# 1500# 2500#; DIN:PN1.0 PN2.5 PN6,PN10,PN14,PN25,PN40,PN64,PN100,PN160, PN250,PN320,PN400; JIS:B2220(30K) JIS2238(40K,63K) JIS3451(F15,F12); BS4504: PN6,PN10,PN16,PN25,PN40; EN1092:PN6,PN10,PN16,PN25,PN63,PN100 | |

| Flange facing: | Raised face, Flat face, Ring Joint face, etc | |

| Standard | ASME,ANSI B16.5; ANSI B16.48; MSS-SP44 DIN2631 EN1092-1 BS4504 BS3293 JIS B2220 DIN 2448 | |

| Material | ASTM | Carbon steel: ASTM A105, A105N, JIS SS400, SF440A, RST37.2/C22.8/P25GH/S235JRG2, Q235/20Mn |

| Stainless steel: ASTM A182 F304/F316/F317/F321 etc. | ||

| Alloy Steel:ASTM A182 F1,F5,F9,F11,F12,F22 etc. | ||

| GB | 10#,20#,20G,23g,20R,Q235,16Mn, 16MnR,1Cr5Mo,

12CrMo, 12CrMoG, 12Cr1Mo |

|

| Surface | anti rust black painted, anti rust oil, galvanizing | |

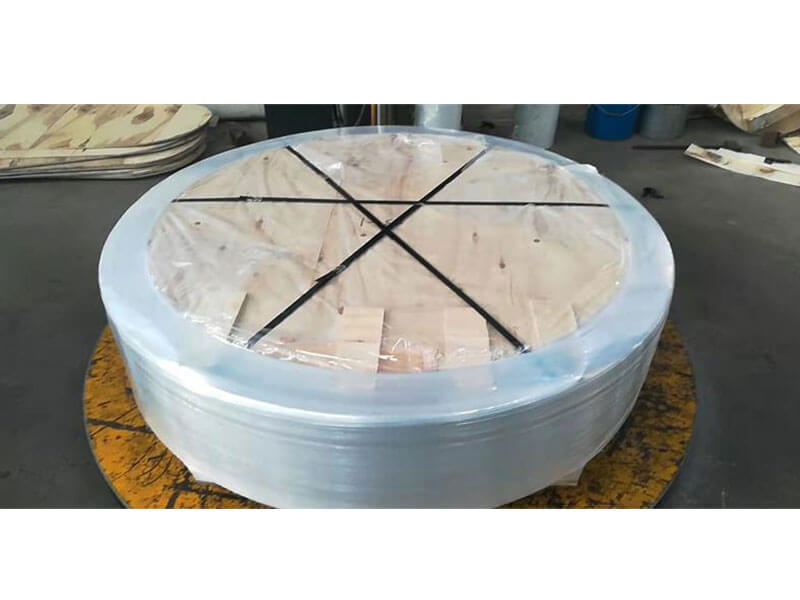

| Packing | In wooded cases or pallets, or as for clients’ requirements | |

| Usage | Petroleum, chemical, machinery, boiler,electric power, shipbuilding, papermaking, construction, etc | |

| Certification | API CE and ISO 9001:2015 GOST | |

| Surface finish: | stock finish, spiral serrated, water lines | |

| Process: | forged, ring rolled and heat treatment | |

| Connection: | Welding | |

| Technical: | Forged | |

| Third part inspect | BV, SGS, LOIYD, TUV, and other party alloyed by clients | |

| special design | as your drawing | |

| Mill Test Certificate | EN 10204/3.1B,EN 10204/3.2B | |

| Payment: | T/T OR L/C | |

| Delivery time: | At the earliest, within the period required by customer | |

点击空白处返回

![]()

- Description