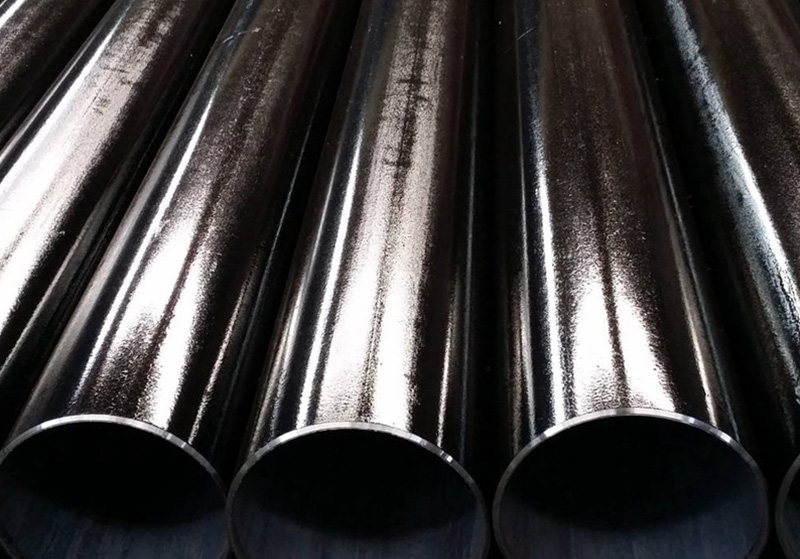

HFW steel pipe

HFW or high-frenquency longitudinal-seam steel pipe is produced from individual sheets or coils that are cold formed into a cylindrical shape, an electric current is used to heat the edges of the strip for fusion welding, continuous forming, and cut to required lengths.

The range of production:

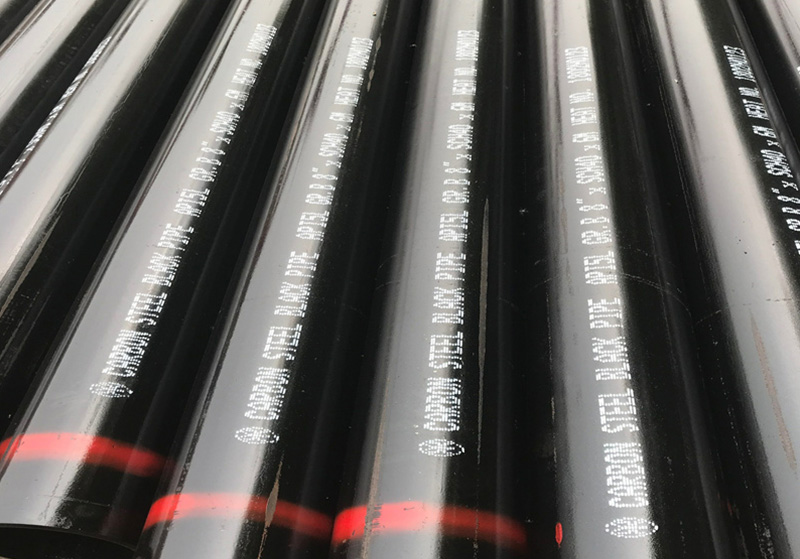

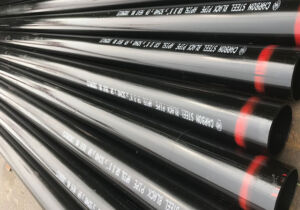

OD: 1/2” -24 “(21.3mm -609mm)

W.T: SCH10-40(2mm to 20mm)

Standard: API 5L/ASTM A53/A252/A500,EN10217/10296. etc.

Materials: X42, X52, X60,Q235B, Q345B, GR.B,S275, S275J0H, S355JOH, SS400

Length: 5.8M/6M/12M/18M fixed length, SRL/DRL

HFW feature and application:

HFW features: simple production process, high production efficiency, low cost, fast delivery

HFW steel pipes are mainly used in water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction.

Used for liquid transportation: water supply and drainage.

Used for gas transportation: gas, steam, liquefied petroleum gas.

For structural purposes: as piling pipes, as bridges; pipes for wharves, roads, building structures, etc.