We specialized in the pipe anti-corrosion field, the products cover the Liquid Epoxy,2LPE/2LPP, 3LPE/3LPP,FBE/2FBE, thermal insulation pipes, which are widely used in the oil & gas, water transmission, fire fighting, civil engineering, offshore, chemical and power projects.

Liquid Epoxy coating: AWWA C210-2015

FBE: AWWA C 213-2015

Cement Mortar Lining: BS 534-1990, AWWA C205-2001

Bitumen Coating: BS534-1990

3LPE / 3LPP Coating: DIN 30670-2012, CAN/ CSA Z245.21-2010 ISO21809-1-2011 SY/T 0413-2016, GB/T 23257-2017

2LPE / 2LPP Coating: SY/T0413-2016, GB/T23257-2017, ISO21809-1-2011

Fusion-Bond-Epoxy) FBE: SY/T 0315-2013, AWWA C213-2015, CAN/CSA Z245.20-2010, ISO21809-2-2011, API RP 5L9-2015

Bitumen coating/ Enamel & tape hot-applied : BS534-1990, AWWA203-2015, AWWA214-2018

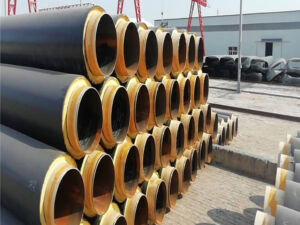

Polyurethane Insulated coating: SY/T 0415-1996, CJ/T 114-2000, EN253-2019

Shall process and blasting before coating -Sa 2.5

Process follow chart of internal & external coating

Bare pipe examination – high pressure flushing- medium frequency pre-heating- blasting – internal blowing & wiping – blasting inspection- pipe ends taping – pipe heating – FBE spraying – adhesive extrusion-PE/PP – Holiday inspection- coating cutback- coating inspection – pipe marking – delivery

Pre- heating- blasting – pipe ends taping- blasting inspection – inside blowing & internal coating -surface drying- curing & coating inspection – pipe marking – delivery