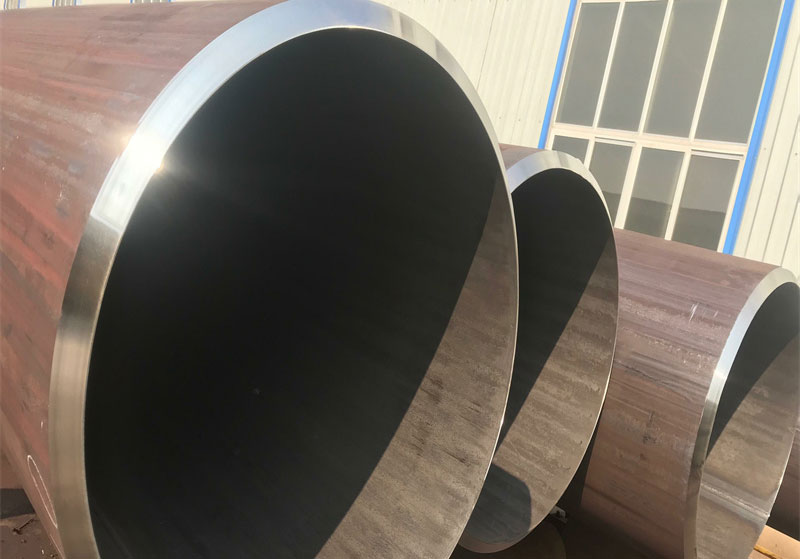

SAWL steel pipe

SAWL or Submerged Arc Welding Longitudinally steel pipe is a kind of straight seam steel pipe. The welding process used is submerged arc welding technology, which is welded with filler and submerged arc with particle protection flux. The production process of submerged arc steel pipe includes JCOE forming technology and rolling forming submerged arc welding technology. When the diameter is large, two steel plates may be used for rolling, which will form a phenomenon of double welds.

The range of production:

OD: 14” -56“(355.6mm -1422mm)

W.T: 0.3”-1.5”(8mm to 50mm)

Standard: API 5L/A252/A500,/A572/A672/671/EN 10219/EN10210/10217. etc.

Materials: X42, X52, X60,Q235B, Q345B, GR.B,S275, S275J0H, S355JOH, SS400,SK52

Length: 6/12

Packing: Loose packing

SAWL application:

Submerged arc welding has a large penetration depth, high productivity, and a high degree of mechanized operation, so it is suitable for welding long welds of medium and thick plate structures. It is widely used in manufacturing sectors such as shipbuilding, boilers and pressure vessels, bridges, hoisting machinery, railway vehicles, engineering machinery, heavy machinery and metallurgical machinery, nuclear power plant structures, and marine structures.