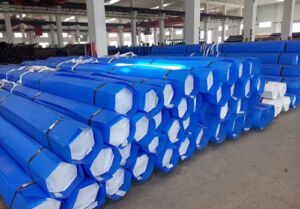

TUBE FOR PRESSURE PURPOSES

It is available to manufacture pipeline, vessel,equipment,pipe fittings and steel structure.

| Standard | Material Grade |

| EN 10216-1 | P195TR1,P195TR2,P235TR1.P235TR2.P265TR1,P265TR2 |

| EN 10216-2 | P195GH,P235GH,P265GH,13CrMo-5,10CrMo9-10 |

Manufacturing process of the hot rolled seamless steel pipe

We produce technology advanced hot rolled seamless steel tubes using continuous tube rolling mills. The hot rolling process consists of steel billet → heating → punching → three-roller skew rolling → tube knockout → tube diameter reducing → cooling → semi-finished pipe → straitening → water pressure test → labeling → warehouse entry.

Diameter: from 3″-20″

Schedule: SCH20 to SCH160

Length: 5.8 M/6 M /12 M fix, Random Length, SRL, DRL

Standard: GB/T8162, GB/T8163, ASTM A106, A53, ASTM A252, API 5L, DIN17175, EN10216, JIS3454, GOST 8732-78 etc

Grade: 20#, 45#, GR.B, X42-X60, P265TR1, Q345B, Q345C, S355JRH, S355J0H, ST52 etc

External Coating: 3PE, FBE, Cement Coating etc

SGS,BV,DNV,TUV,MOODY or other third party inspection is acceptable

Classification

The hot rolled steel pipe is categorized into common steel pipe, medium and low pressure boiler pipe, high pressure boiler steel tube, alloy tube, stainless steel pipe, oil cracking pipe and geology steel tube.

Features

Our hot rolled steel pipes offer various outstanding features and comparative advantages, as is manifested by the following. In our way of manufacturing the hot rolled steel pipe, the cast structure of steel ingot can be broken, the grains of steel are refined, and the defects of the micro-structure of steel are eliminated, resulting in improved mechanical properties and denser micro-structures of the steel product. For specifications of our hot rolled steel pipes, please see the form attached.