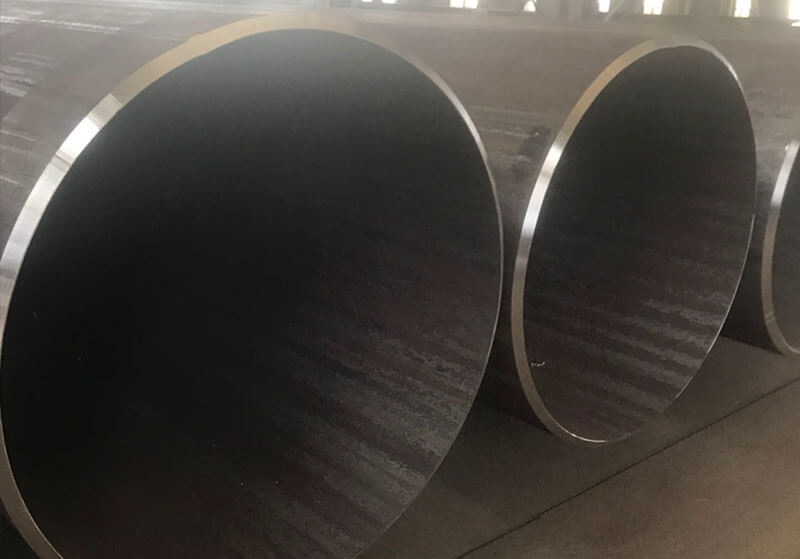

Submerged arc welded steel pipe

Longitudinal Submerged Arc Welding is a specific welding technique used in pipe production where the finished product requires a particularly high wall thickness due to high internal or external pressures.

With this in mind the main applications of LSAW pipes include oil, natural gas, gas, central heating, water supply, sewage treatment and other similar uses.

Standard: ASTM A252, API 5L, GB/T3091, EN10219, EN10210, EN10217 etc.

Advantage:

The production process of submerged arc welded pipe is flexible and can produce any specification and wall thickness within the product range, and the production efficiency is lower than that of high-frequency straight seam welded steel pipe and spiral welded steel pipe. The biggest advantage of straight seam submerged arc welded pipe is that it can produce specifications and models that cannot be produced by high-frequency steel pipes, spiral steel pipes, and even seamless steel pipes. The production cost of straight seam submerged arc welded pipe is higher than that of high-frequency steel pipe and spiral steel pipe, but there is a lot of room for price discounts compared with seamless steel pipe.

Application:

Longitudinal submerged arc welded pipes are widely used in domestic heavy steel structure engineering, fluid pipeline engineering, and foundation piling engineering.