أنابيب الصلب المضادة للتآكل المتفجرات من مخلفات الحرب

تستخدم الأنابيب الفولاذية المقاومة للتآكل في صناعة البترول, كيميائية, غاز, حرارة, معالجة مياه الصرف الصحي, ماء, الجسور, أنابيب الصلب وغيرها من المجالات الهندسية, وهي مقسمة إلى الفئات التالية.

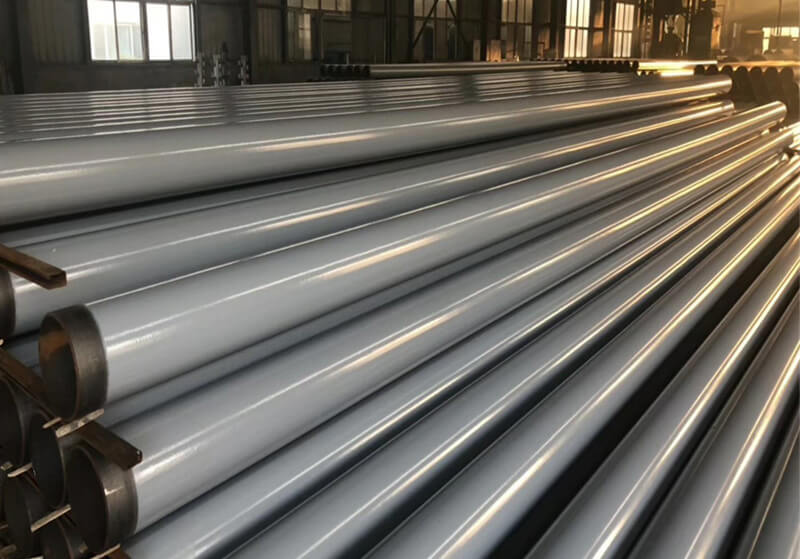

3أنابيب الصلب المطلية بـ LPE

يعد نظام منع التآكل من البولي إيثيلين ثلاثي الطبقات أحد الأنظمة التقنية الرئيسية لحماية التآكل في خطوط الأنابيب المدفونة محليًا وخارجيًا. لديها مقاومة جيدة للتآكل, امتصاص منخفض للماء وقوة ميكانيكية عالية. لقد تم استخدامه على نطاق واسع في مجال نقل المياه المدفونة, نقل الغاز ونقل خطوط الأنابيب في السنوات الأخيرة.

جيجابايت/T23257-2009 المعيار الفني لطلاء البولي إيثيلين المضاد للتآكل لخطوط الأنابيب الفولاذية المدفونة

سي/T0413-2002 المعيار الفني لطبقة البولي إيثيلين المقاومة للتآكل لخطوط الأنابيب الفولاذية المدفونة

DIN30670-2012 المعايير الفنية لطلاءات البولي إيثيلين للأنابيب والتجهيزات الفولاذية في ألمانيا

يمكن/CSA-Z245.21-M92 المعيار الفني الكندي للطلاء المضاد للتآكل لأنابيب البولي إيثيلين على الجدار الخارجي

يستخدم: وتستخدم على نطاق واسع المنتجات في خطوط أنابيب النفط, خطوط أنابيب الغاز الطبيعي, أنابيب التدفئة, خطوط أنابيب المياه.

3ص (مادة البولي بروبيلين) أنابيب الصلب المطلية بالمتفجرات من مخلفات الحرب

DIN30678 المواصفات الفنية القياسية لطلاء مادة البولي بروبيلين للأنابيب الفولاذية وتجهيزات الأنابيب

3مزايا طلاء PP:

يشير الأنبوب الفولاذي المطلي بـ 3PP إلى الأنابيب الفولاذية ذات ثلاث طبقات من PP(مادة البولي بروبيلين) طلاء. إنه يوفر قوة كهربائية عالية, مقاومة الأحماض, مقاومة القلويات, تحمل الملح, العزل الكهربائي, عمر خدمة طويل, التحمل الحراري ومقاومة التأثير. بسبب تكنولوجيا طلاء الأنابيب الفولاذية المتقدمة, يتميز هذا النوع من الأنابيب الفولاذية المطلية بالبلاستيك بطبقات جيدة الارتباط.

3تطبيقات طلاء PP:

الأنابيب الفولاذية المطلية بـ 3PP مناسبة لنقل المواد الخاصة, مثل المواد ذات درجة الحرارة العالية, لأنه يوفر قوة كهربائية عالية, مقاومة الأحماض, مقاومة القلويات, تحمل الملح, العزل الكهربائي, عمر خدمة طويل, التحمل الحراري ومقاوم للصدمات.

أنابيب الصلب المطلية بـ ERW المطلية بـ FBE

أنبوب الطلاء FBE عبارة عن أنبوب فولاذي مطلي بالإيبوكسي Fusion Bonded Epoxy. وهو عبارة عن راتينج حراري مطبق خارجيًا للأنابيب. على شكل مسحوق جاف بسماكة 300-600 ميكرون على سطح الأنبوب الساخن. بمجرد طلاء FBE على سطح الأنبوب, يوفر فيلم FBE سطحًا صلبًا للغاية مع التصاق رائع بسطح الأنبوب. طبقة FBE بشكل متساوي ولها مقاومة جيدة للتفاعل الكيميائي.

الاستفادة من أنبوب الطلاء FBE:

(1) مريحة للرش, لا تلوث, مقاومة ممتازة لدرجات الحرارة العالية (-40درجة مئوية إلى 85 درجة مئوية)

(2) قوة عالية وأداء مضاد للانحناء;

(3) التصاق قوي, سلامة جيدة, مكافحة الإجهاد التربة وارتداء.

عادةً ما يتم دفن الأنابيب الفولاذية المطلية بـ FBE في التربة وتحت الماء بين -40 درجة مئوية إلى 85 درجة مئوية.

على الجانب الآخر, العيب في أنبوب FBE هو أنه لا يتمتع بمقاومة جيدة للأداء الميكانيكي والظروف الرطبة.

طلاء FBE الخاص بنا يؤدي المعايير وفقًا لـ SY/T0315, يمكن/سسا Z245.20, Awwa C213, س/CNPC38 الخ.

يستخدم: تستخدم على نطاق واسع في الأرض, مقاومة التآكل لخطوط الأنابيب تحت الماء.

طلاء عازل من مادة البولي يوريثين أنابيب الصلب المتفجرات من مخلفات الحرب

أنبوب الحفاظ على الحرارة المباشر للبولي يوريثان هو أنبوب الحفاظ على الحرارة المباشر المدفون المباشر مع أداء جيد للحفاظ على الحرارة, السلامة والموثوقية, وتكلفة هندسية منخفضة. لا يحتوي أنبوب العزل الحراري المدفون على التكنولوجيا المتقدمة والأداء العملي الذي يصعب مقارنته مع الخندق التقليدي وخط أنابيب وضع العلوم العامة, ولكن لديها أيضا فوائد اجتماعية واقتصادية واضحة, وهو أيضًا مقياس قوي للتدفئة وتوفير الطاقة.

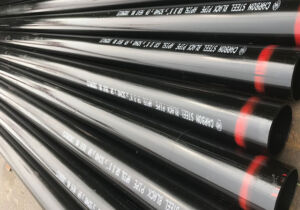

يتميز باستخدام متعددة الأغراض لمنع انتشار النار وأداء السلامة من الحرائق الجيدة. أنبوب عزل سترة سوداء يشمل أنبوب الفولاذ الحلزوني, أنابيب فولاذية مستقيمة وأنابيب فولاذية سلسة. الطبقة الخارجية مصنوعة من البولي إيثيلين الأسود وتسمى أنبوب عزل سترة أسود.