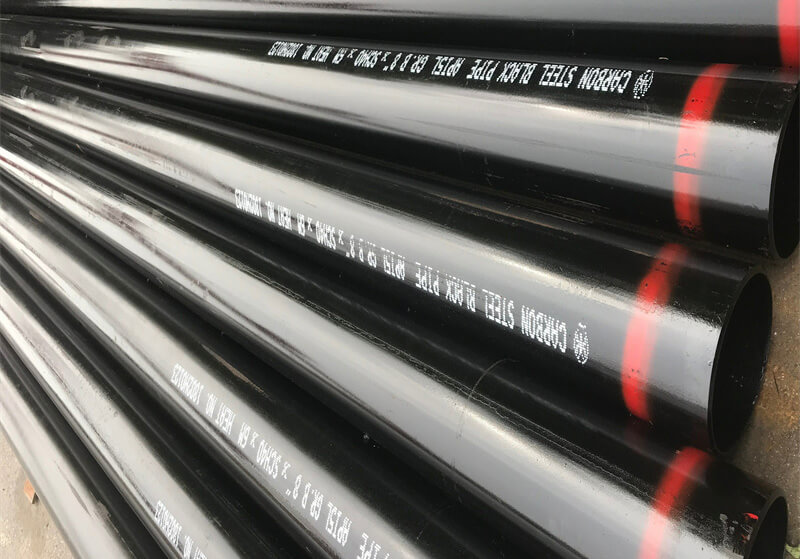

Conduite de canalisation API 5L, Huile & Conduite de gaz

1. De diamètre: 114.3MM – 660.4MM (4″-26″)

2. Épaisseur: 3.0-20.0MM

3. Longueur: 3M-18M

4. Taper: ERW (Résistance électrique soudée) Tuyaux en acier, HFI (Induction à haute fréquence) Tuyaux en acier, Hfw (Soudage à haute fréquence) Tuyaux en acier

5. Standard: API 5L(ISO 3183) PSL1 / PSL2: Gr.B-X80, GB / T 9711.1, GB / T 9711.2, ASTM A53: Gr.A / Gr.B, ASTM A500: Gr.A / Gr.B / Gr.C / Gr.D, ASTMA252: Gr. 1 / Gr. 2 / Gr. 3, EN10219 / EN10210: S275 / S355JRH / J0H / J2H, AS / NZS 1163

6. Usages: Tuyaux en acier soudé pour une utilisation dans le système de transport de pipeline dans le pétrole et le gaz naturel (huile & gaz) industries, gazoduc, de construction & construction.

7. Analyse chimique (%):

| Standard | Type de tuyau | Classe | Grade | C

max |

Et

max |

MN

max |

P

max |

S

max |

V

max |

NB

max |

De

max |

| API Spec 5L

/ISO 3183 |

SOUDER | PSL1 | L245 B | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – |

| L290 / x42 | 0.26 | – | 1.3 | – | 0.03 | 0.03 | – | – | |||

| L320 / x46 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | |||

| L360 / x52 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | |||

| L390 / x56 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | |||

| L415 / x60 | 0.26 | – | 1.4 | – | 0.03 | 0.03 | – | – | |||

| L450 / x65 | 0.26 | – | 1.45 | – | 0.03 | 0.03 | – | – | |||

| L485 / x70 | 0.26 | – | 1.65 | – | 0.03 | 0.03 | – | – | |||

| Psl2 | L245m / gr.bm | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | ||

| L290m / x42m | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | |||

| L320m / x46m | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | |||

| L360m / x52m | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | – | – | – | |||

| L390m / x56m | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | – | – | – | |||

| L415m / x60m | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | – | – | – | |||

| L450m / x65m | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | – | – | – | |||

| L485m / x70m | 0.12 | 0.45 | 1.7 | 0.025 | 0.015 | – | – | – | |||

| L555m / x80m | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | – | – | – |

Propriétés mécaniques

| Standard | Classe | Grade | Limite d'élasticité (MPA) | Résistance à la traction (MPA) | Élongation (%) |

Y.S / T.S | |

| API Spec 5L / ISO 3183 | PSL1 | L245 / Gr.B | min | 245 | 415 | b | – |

| L290 / x42 | min | 290 | 415 | b | – | ||

| L320 / x46 | min | 320 | 435 | b | – | ||

| L360 / x52 | min | 360 | 460 | b | – | ||

| L390 / x56 | min | 390 | 490 | b | – | ||

| L415 / x60 | min | 415 | 520 | b | – | ||

| L450 / x60 | min | 450 | 535 | b | – | ||

| L485 / x70 | min | 485 | 570 | b | – | ||

| Psl2 | L245N / BN

L245M/BM |

min | 245 | 415 | b | – | |

| max | 450 | 760 | b | 0.93 | |||

| L290N / X42N

L290m / x42m |

min | 290 | 415 | b | – | ||

| max | 495 | 760 | b | 0.93 | |||

| L320N / X46N

L320m / x46m |

min | 320 | 435 | b | – | ||

| max | 525 | 760 | b | 0.93 | |||

| L360N / X52N

L360m / x52m |

min | 360 | 460 | b | – | ||

| max | 530 | 760 | b | 0.93 | |||

| L390n / x56n

L390m / x56m |

min | 390 | 490 | b | – | ||

| max | 545 | 760 | b | 0.93 | |||

| L415N / X60N

L415m / x60m |

min | 415 | 520 | b | – | ||

| max | 565 | 760 | b | 0.93 | |||

| L450m / x65m | min | 450 | 535 | b | – | ||

| max | 600 | 760 | b | 0.93 | |||

| L485m / x70m | min | 485 | 570 | b | – | ||

| max | 635 | 760 | b | 0.93 | |||

| L555m / x80m | min | 555 | 625 | b | – | ||

| max | 705 | 825 | b | 0.93 |