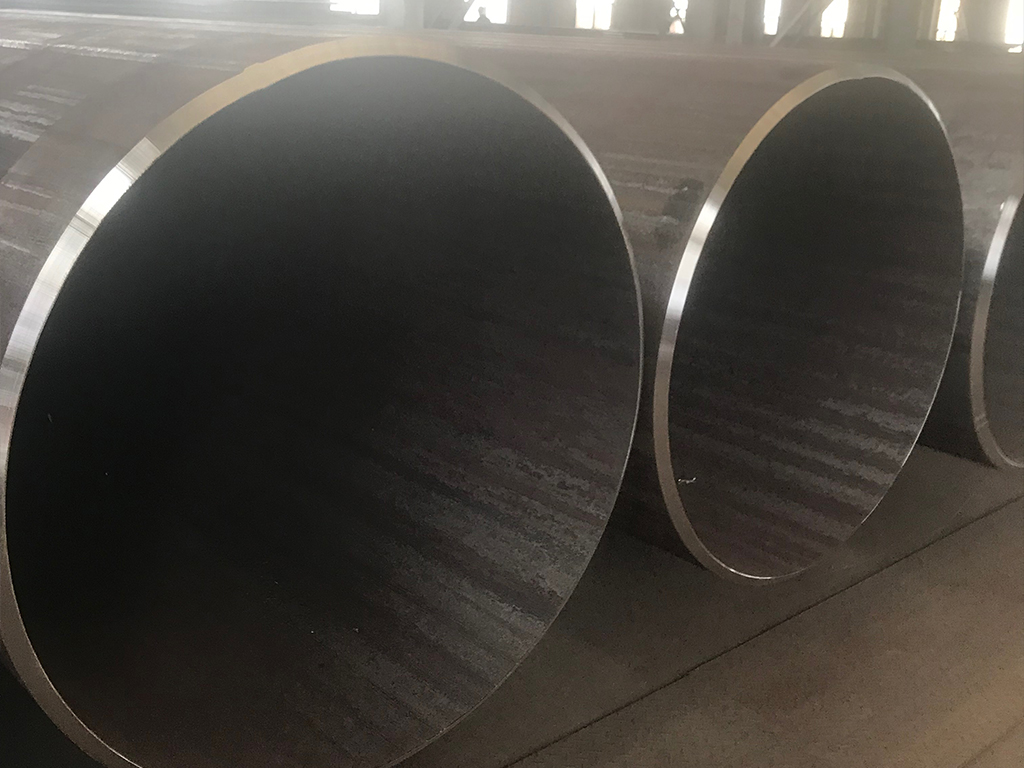

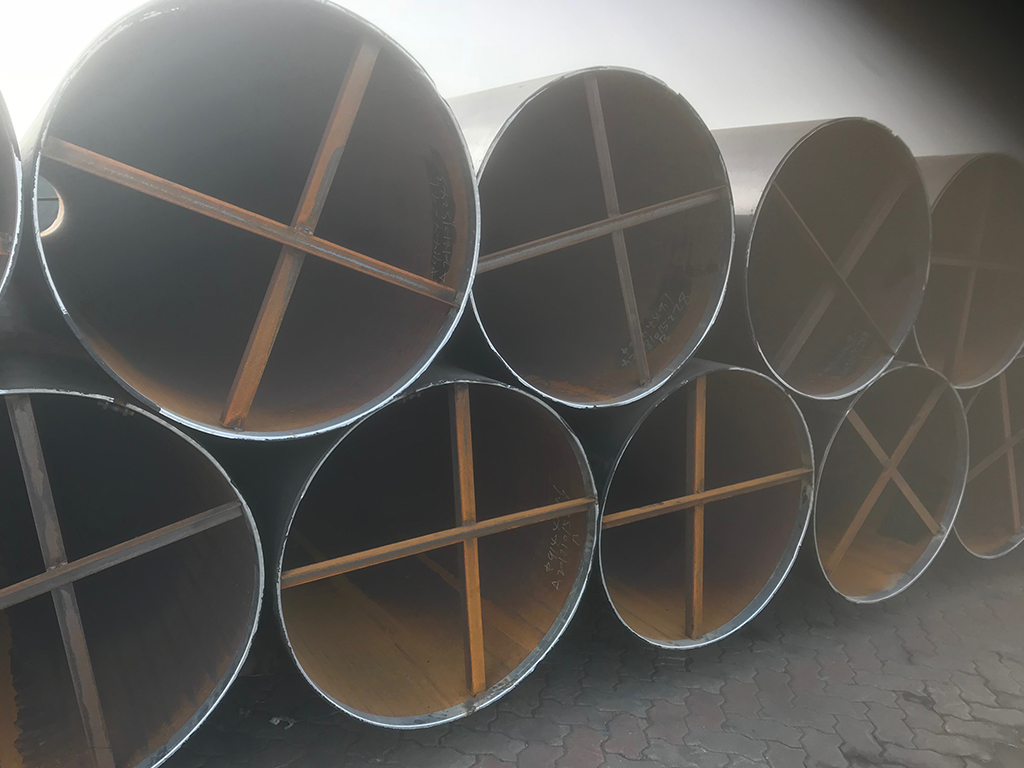

رأى (lsaw/عدة) أنبوب الصلب, خط أنابيب المياه

من خلال إجراء عمليات اكتشاف قياسية غير مدمرة على أنابيب LSAW الخاصة بنا, نحن نضمن أن تكون أنابيبنا تخدم عملائنا بشكل جيد. تعد أنابيب LSAW Steel الخاصة بنا أنابيب مثالية لهندسة خطوط الأنابيب واسعة النطاق, البترول, نقل المياه أو الغاز الطبيعي وبناء شبكة أنابيب الحضرية وتراكمها.

عملية:

لزو (طولية غمر اللحام), uo(أوه), RB(RBE), JCO(jcoe)

DSAW (قوس مزدوج مغمورة)

مقاس:

القطر الخارجي: 406.4MM-1422mm(16"-56")

سمك الجدار: 9.5MM-50mm

طول: 6mtr-12.5mtr

معايير الجودة:

أنبوب خط API 5L للزيت والغاز

مواصفات ASTM A53 القياسية للأنابيب, فُولاَذ, أسود وساخن, مغلفة بالزنك, ملحومة وسلس

من 2458 أنابيب وأنابيب الصلب الملحومة

EN10210 مقاطع جوفاء الهيكلية الساخنة من غيرها من الفولاذ والحبوب الفاخرة

EN10219 أقسام جوفاء هيكلية من البرودة من غيرها من الفولاذ غير المليئة بالحبوب

GB/T3091 أنابيب فولاذية ملحومة لتسليم السائل منخفض الضغط والبناء

GB/T9711 صناعات البترول والغاز الطبيعي–أنابيب الصلب لخطوط الأنابيب

معيار الطلاء:

ANSI/AWWA C104/A21.4 المعيار الوطني الأمريكي للبطانة الأسمنتية للأنابيب الحديد الدكتايل والتجهيزات للمياه

ISO 21809: صناعات البترول والغاز الطبيعي — الطلاءات الخارجية لخطوط الأنابيب المدفونة أو المغمورة المستخدمة في أنظمة نقل خطوط الأنابيب

من 30670: الطلاء البولي إيثيلين من الأنابيب الفولاذية والتجهيزات

Awwa C210: الطلاء والبطانات السائلة epoxy لأنابيب المياه الفولاذية والتجهيزات

Awwa C213: طلاء الايبوكسي المربوط بالاندماج للداخلية والخارجية لخطوط أنابيب المياه الفولاذية

نهاية:

نهايات عادي/مربع (قطع مستقيم, رأى قطع, وقطع الشعلة), أو نهايات مشطوفة

سطح:

زيت خفيف, تراجع الساخنة المجلفن, رسمت أسود, طلاء الورنيش/زيت الصدأ, الطلاء الواقي (الايبوكسي, اندماج بوند الايبوكسي, 3-الطبقات PE)